Nails they all are but there is a need to name it rightly. Functionally they might be all equal but lengths can vary and this is from where the differences arise. Nails are broadly divided into three categories – nails that are smaller than an inch in length are no longer called nails but are known as brads and the biggest one above 4 inches length are called spikes. The intermediary range between 1 inch and 4 inches is known as nails. So, next time you go to the hardware shop, this information can be useful. But this classification is not as rigid as it seems on paper, so, as long as you can specify the length you can be sure to get the right nail that you are looking for. Nails are perhaps the most primitive fasteners that have been used through various stages of civilization.

Mostly used fasteners

If you are asked to name the most widely used fasteners then there should be no confusion in naming nails. This metallic fastener can be made from various metals like stainless steel, brass, copper and aluminum depending on the nature of use and currently there rte at least 300 different types of nails manufactured in the US. Stainless steel nails are most widely used as it does not rust nor does it get corroded and its shiny looks remain intact for prolonged period. The quality of fasteners is determined by its tensile strength and shear value of the metal.

Stronger nails

The strength of nails is inherited from the metal from which it is drawn. But the fastening ability of stainless steel nails or any other nails can be enhanced by tweaking the design of the shank. Plain, smooth and round shanks are usually produced but for special requirements that need permanent grip the shanks may be fluted, have annular grooves and serrations or may have helical threads that reinforce the fastening strength. For better adherence inside the surface, stainless steel nails can be coated with thermoplastic that heats up during hammering that causes friction. When the soft plastic layer cools down, it creates an additional bonding that locks the nails in its place.

Nails are evolving

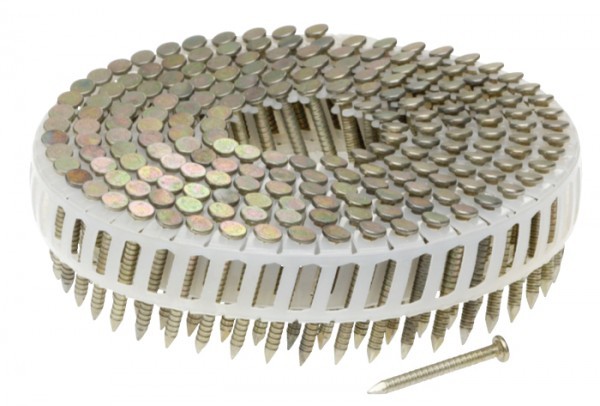

Nails are directly related to building and construction work besides making furniture and other carpentry work. As new building materials are being introduced, manufacturers get busy to design and develop new nails to meet the needs. Different kinds of nails are used for concrete, sheet metal, wall board, tile roofing, rain gutters, shingles and hardwood flooring. Special kinds of nails are used in aerospace industry. Nails can be driven by hammers but special type of nails that come in coils have to be driven by using pneumatic nail guns.

The success of a project depends on the right selection of nails. Wrong selection can turn out to be expensive and delay the project. Selecting the right material and proper design of nails contribute to good finish that enhances the aesthetic value of the construction.